Product Series

Custom Alcohol Free Baby Wipes

-

Hypoallergenic Baby Wipes Unscented Natural Care with Aloe Vera

99% Purified Water Gentle Soft Baby Wipes Safe for Sensitive Skin 80PCS

Suxiang baby wipe size is 4.33’’ x 6.3’’ which is made of 40gsm spun lace non-wo...

Suxiang baby wipe size is 4.33’’ x 6.3’’ which is made of 40gsm spun lace non-wo... -

Hand & Face Wipes Cleansing & Moisturizing Baby Wipes Fragrance Free

Water-Based & Alcohol-Free Baby Wipes 10pcs 40pcs 80pcs Optional for Face

The appearance of the shark baby is full of childlike interest and very cute. Ou...

The appearance of the shark baby is full of childlike interest and very cute. Ou... -

Cleansing & Moisturizing Hand and Face Cleansing Wipes Sustainable Organic Baby Wipes

Biodegradable Hypoallergenic Baby Wipe Plastic-Free & Plant Based

Our baby are made with 99.5% purified water, no harsh ingredients, 0% alcohol, f...

Our baby are made with 99.5% purified water, no harsh ingredients, 0% alcohol, f... -

Pink Squirrel Unscented Baby Wipes Sensitive Skin, Soft Durable & 99% Water Based, Gentle & Hypoallergenic for Babies & Adults

Our unscented baby wipes gently clean and help protect baby’s delicate skin. Whe...

Our unscented baby wipes gently clean and help protect baby’s delicate skin. Whe... -

Pink Rabbit Gentle Baby Wipes Fragrance Free Hypoallergenic& Sensitive Skin Ultra-Soft Baby Wipes

Suxiang baby wipes are made with 99% pure water, ensuring a hypoallergenic and i...

Suxiang baby wipes are made with 99% pure water, ensuring a hypoallergenic and i...

About us

We are a disposable wipes manufacturer.

Yangzhou Suxiang Medical Instrument Co., Ltd., specializing in the production, processing and sales of disposable wipes, the main products are medical alcohol pads, medical povidone iodine pads, screen cleaning wipes, disinfectant wipes, baby wipes, multifunctional wipes, first aid kit accessories, advertising wipes. We are China OEM Hypoallergenic Sensitive Baby Wipes Suppliers and Custom Alcohol Free Baby Wipes Manufacturers. Our company plant area is 4000 square meters, has 60+ employees. In recent years, the company has introduced a series of advanced equipment, with single wet wipes, multiple wet wipes packaging machine more than 100 sets, the daily output can reach 10 million bags. We also support OEM, ODM, to provide customers with personalized customized services. In addition, our company has obtained ISO13485, ISO9001, BSCI certification, products have CE, FDA, NDC, MSDS, SGS, chemical safety transportation and other foreign certificates. We focus on developing high-quality products for top-end markets. And our products sell well throughout the country, exported to the United States, Europe, Japan, Southeast Asia and other countries and regions.

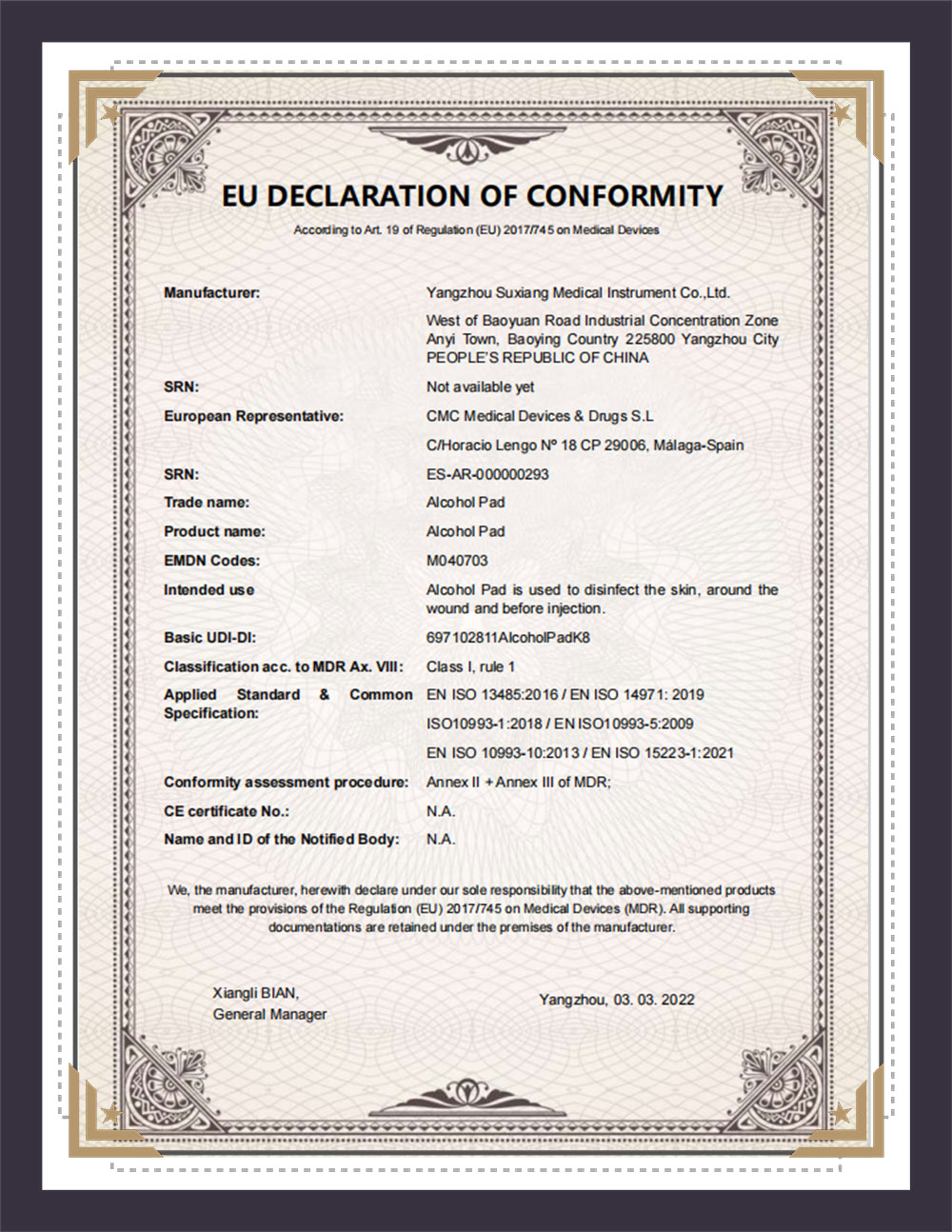

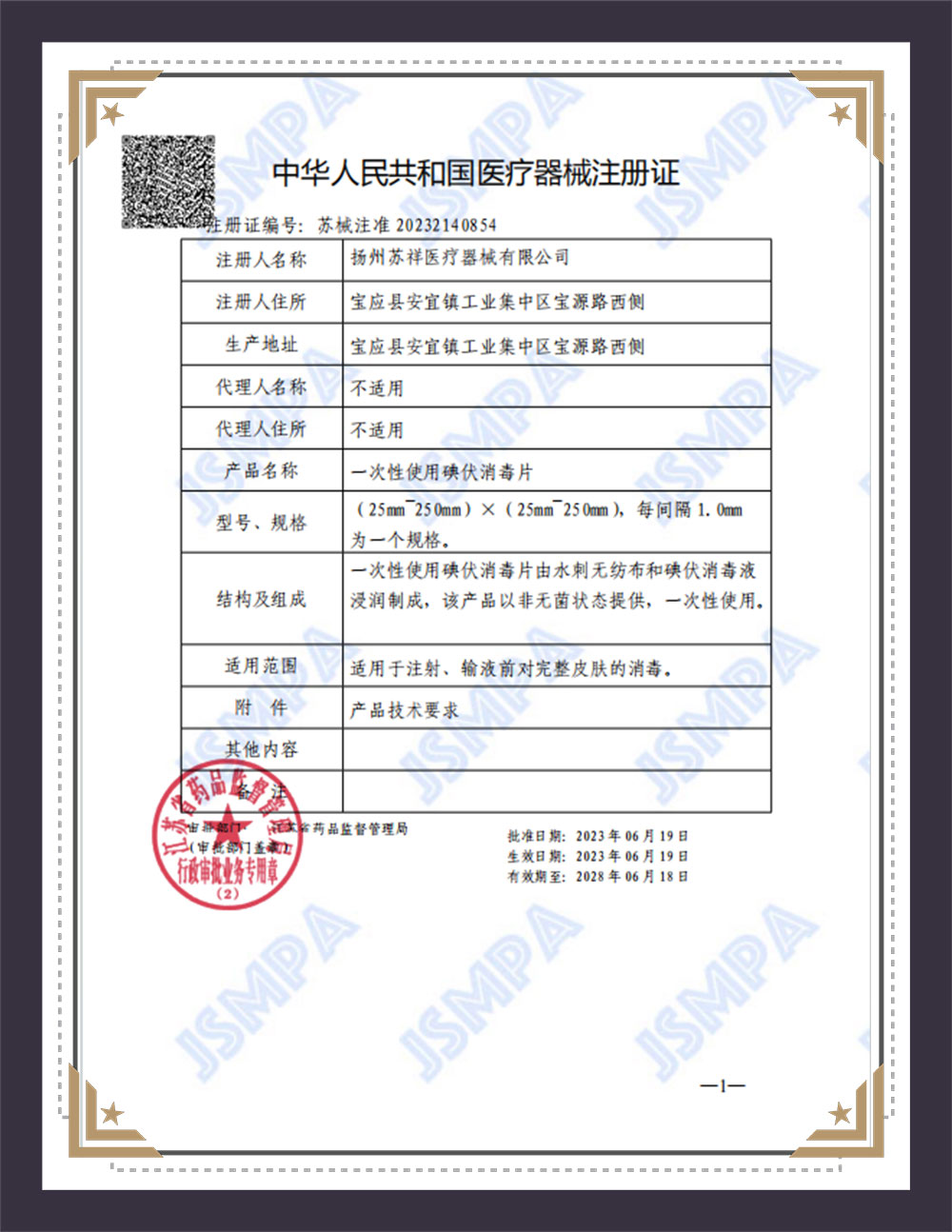

Honor & Qualification

Choose comes from trust, and cooperation

comes from honesty.

NEWS

Alcohol-Free Baby Wipes Manufacturers Produce Alcohol-Free Baby Wipes What are the benefits of natural ingredients for baby skin?

Manufacturers of alcohol-free baby wipes choose to use natural ingredients during the production process, which have many benefits for baby's skin. These natural ingredients are not only mild and non-irritating, but also rich in nutrients and moisturizing factors that are beneficial to baby's skin.Plant extracts in natural ingredients usually have antibacterial and anti-inflammatory effects, which can effectively fight bacteria on the baby's skin surface and prevent skin infections. This is especially important for babies who have just been exposed to the external environment because their immune systems are not fully developed and their skin barriers are relatively weak.

Moisturizing factors in natural ingredients, such as glycerin, hyaluronic acid, etc., can effectively lock in skin moisture and keep baby's skin moist and elastic. This is very helpful in preventing dry, flaky skin in babies.

Some natural ingredients also have soothing and calming effects, such as chamomile, aloe vera, etc. They can relieve discomfort caused by external stimulation of the baby's skin, such as redness, swelling, itching, etc., and help maintain the health of the baby's skin.

Alcohol-free baby wipes avoid the potential irritating and drying effects of alcohol on baby's skin. Although alcohol has a bactericidal effect, it can also destroy the natural oils on the skin surface, causing the skin to lose moisture, which is not suitable for babies' delicate skin.

Manufacturers of alcohol-free baby wipes choose to use natural ingredients, which are not only mild and non-irritating, but also antibacterial, moisturizing and soothing to baby's skin, effectively preventing skin problems and promoting the healthy development of baby's skin. Therefore, when choosing baby wipes, parents can give priority to alcohol-free products that use natural ingredients to provide the best care for their baby's skin.

How to properly conduct a small area trial to ensure your baby does not have an allergic reaction to alcohol-free baby wipes?

To make sure your baby doesn't have an allergic reaction to alcohol-free baby wipes, a small trial is a very important step. The following will introduce in detail how to correctly conduct a small area trial:Choose an area where the baby's skin is more hidden and less susceptible to friction, such as the inside of the arm or the back of the leg. This can avoid skin damage or discomfort caused by friction or external stimulation during the trial.

Clean and dry the selected trial area. Make sure there is no dirt, sweat or other residue on the skin surface that could affect the accuracy of the test. Use mild water and a soft towel to gently wipe the skin, then wait a moment for the skin to dry naturally.

Take an alcohol-free baby wipe and gently press it on the trial area, making sure the wipe is in full contact with the skin. Do not rub or rub the skin hard to avoid irritation.

Observe the reaction of the trial area. Within a few minutes to a few hours after trying it, pay close attention to your skin for any allergic symptoms such as redness, swelling, itching, or rashes. If you find any discomfort or abnormal reaction, you should stop using it immediately and rinse the trial area with clean water.

In addition, even if no allergic reactions occur in a small area trial, it does not mean that babies will not be allergic to all alcohol-free baby wipes. Different brands of wet wipes may have different ingredients, so it is recommended that parents choose products from different brands when trying them out to get a more comprehensive understanding of how babies react to different products.

If the baby does not experience allergic reactions after trying it on a small area, parents can gradually expand the scope of use, but they still need to continue to observe the baby's skin condition. If any discomfort or abnormal reaction occurs during use, you should stop using it immediately and consult a doctor for advice.

By correctly conducting a small-area trial, parents can use alcohol-free baby wipes with greater confidence, providing safe and comfortable care for their baby's skin.